Industries We Serve

Tunco Manufacturing provides tungsten carbide tools and solutions for a variety of industries. Explore some of our top industries below.

Foundries

Tunco Manufacturing is a proud supplier of files and tungsten carbide tools to clients in the foundry industry. We have decades of experience developing effective files and tools and meeting foundries’ needs during the degating and finishing process of casting.

Tire Manufacturing

Tunco is the largest supplier of uniformity correction grinding wheels to OEM tire manufacturers. When it comes to tires, maintaining an even tread across the whole tire is important, but rubber grinding tools can wear out easily. Across the tire manufacturing industry, we are a trusted provider of replacement uniformity correction wheels and spindles.

Our customers include:

- Akron Standard Machine

- Akron Special Machinery

- Micro-Poise

- Firwood

- Spadone

- Goodyear

- Michelin

- Bridgestone/Firestone

- Collmann

- Matteuzzi

Conveyor Systems & Gripping Components

Many industries rely on conveyor systems to move materials for processing. Over time, these conveyor belts can wear down and conveyor rollers can lose friction, rendering a conveyer system less effective because speed and stops are more difficult to control. Keeping the grip on your conveyor rollers in good condition is of vital importance, especially for industries that work in harsh weather conditions or humid environments where losing friction is a greater hazard. Tunco can also apply abrasive coatings to existing clamps and grippers to improve grip and improve wear life on components along with working with you to develop new parts to best serve your needs.

Tunco Manufacturing’s abrasive coatings (including tungsten carbide coatings and our in-house developed diamond-sharp are the perfect, long-term solution to ensure that your belts stay firmly in place. Our abrasive coatings are more durable than rubber and improve friction, resulting in longer belt life, fewer belt-tracking issues, and reduced energy costs for your conveyor system. Abrasive coatings may be applied in the following ways:

- Friction bands to be mounted on rollers to prevent slippage

- Diverter rollers for separating products or materials

- Coated rollers for feeding products or materials

- Apply coatings to clamps and gripping parts

Shoe Manufacturing

Tunco manufactures and custom-designs tungsten carbide tools to trim, cut, and grind rubber in the shoe manufacturing industry. We offer tools to grind and shape rubber soles for boots or shoes.

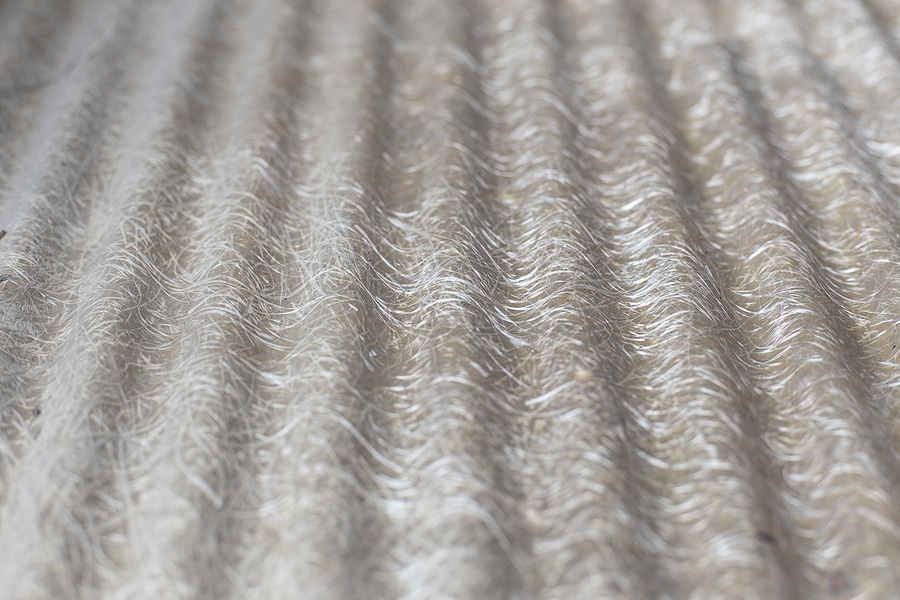

Fiberglass Fabrication & Manufacturing

Tunco crafts custom fiberglass cutting blades, rotary burrs, and other advanced fiberglass cutting tools engineered for precision fiberglass cutting and grinding. Our fiberglass cutting tools are available in plasma, di-carb, and tungsten carbide tool coatings designed to cut efficiently without cracking and clogging your tools with fibers and resin.

Whether you’re looking for solutions for fiberglass fabrication and manufacturing applications, or other fiberglass cutting and sanding industries, our tungsten carbide tools offer long-lasting durability without sacrificing performance.

Get Started

We continue to use state-of-the-art technology and innovations to provide you with the best abrasive-coating tools and tungsten carbide products in the industry. If you’d like to order one of our standard products or need a custom tool, contact us today!